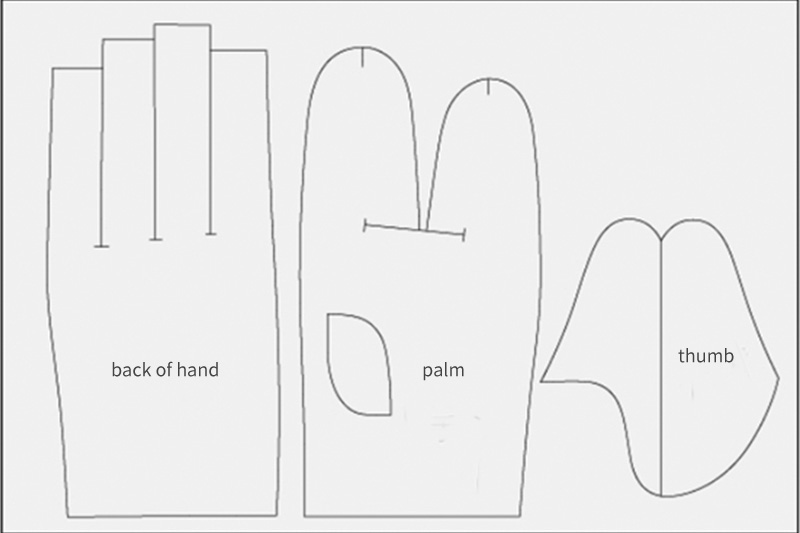

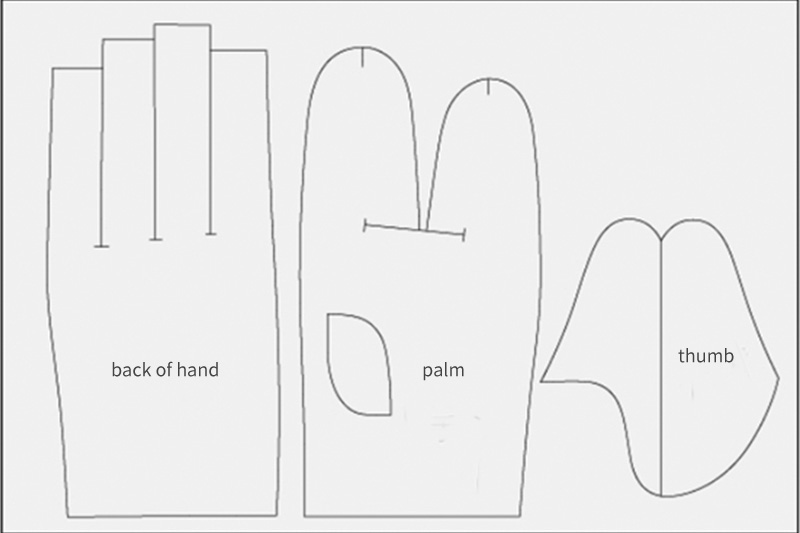

First, we need to understand the structure of the glove

Most fitness gloves structures are divided into: Palm, thumb, back of hand, index finger, middle finger, ring finger, little finger, fourchette, knuckle, wrist, part of the hand between the thumb and the index finger.

Version

Our gloves are of standard European size. It can also be customized according to customer requirements.Size

There are sizes XS, S, M, L, XL, XXL, XXXL, our sizes are usually S, M, L, XL. Accept custom sizes.Then, start making gloves.

First, We must first draw a template with drawings and make a model. After many inspections and tests, mass production.

New product release meeting twice a year, to research and develop new products according to market demand changes and fashion trends. There are professional staff to investigate the market, and a special operation team to analyze the data. At the same time, there are also staff sports experts to experience the experience of using new products and develop new products based on the views of consumers. The annual number of new products reaches 45 styles , including fitness gloves, cycling gloves, baseball gloves, billiard gloves and riding gloves.

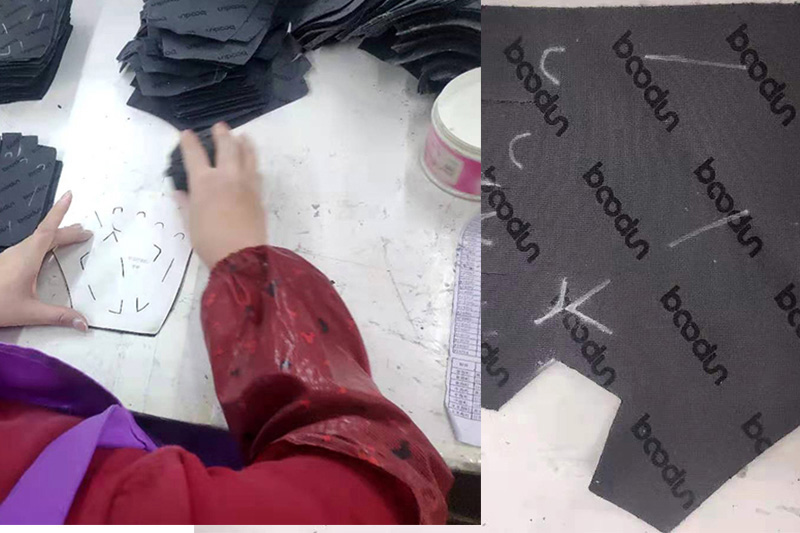

Second, Then cut it out with a machine, according to the design drawings

General processes require printing, such as silicone printing, sublimation printing

Third: use a mold to cut out the materials required for fitness gloves.

Fourth: In order to sew accurately, we have to do a lot of work in the early stage, such as sticking foam, we will draw the line first, see the picture below.

Fifth: Then put on the foam to protect the palms during fitness,

Sixth: Paste the foam, and the cut model fabric, we will use computer-controlled cycle machine with input function or multi-function embroidery machine.

The lines stitched by advanced machines are perfect.

Seventh: Other processes are manual sewing, such as hand back

The fabric on the back of the hand is generally Lycra, ottoman fabric or mesh. Lycra is divided into brushed Lycra, bright Lycra, semi-dull Lycra, and dull Lycra. Hand back crafts include printing, stitching, etc.

For the material of the thumb, we choose to use a terry cloth, because the terry cloth has good sweat absorption. You can use your thumb to wipe sweat during exercise

Sewing process (according to customer requirements)

1. Positioning

Positioning is to fix two or more layers of materials together. Before positioning, you must recognize the front and back of the material and the direction of the pattern. It is generally required that the spigot for positioning is 2~5mm, not too wide, and the surface material should be flat, wrinkle-free and not twisted. Lines, debris, dirty spots, etc. (especially light-colored) are not allowed in the interlayer.

2. Back needle

Inverted stitches are to increase the firmness. In addition to stitching back and forth when the stitching is started and narrowed, stitches need to be stitched back in places where weight is required, such as the two ends of a stitched zipper. Back stitches must fall in the same straight line

3. Trademark

Trademarks are product signs, so you should not be careless. Before the car, you must check whether the graphics of the trademark are clear and whether there is any skewing (including printed labels, woven labels, leather labels, washing labels). Generally, it starts and closes at the bottom of the trademark Needle, 3~4 stitches should be heavier when narrowing the needle, and it must be on a straight line. Sewing in strict accordance with the positioning, the material has positioning holes or painted positioning points, and the trademark must cover the points. Printed labels and woven labels cannot be skewed when stitching.

4. Seam

Sewing is to join two layers of fabric together, which is the main process.After strict procedures and procedures, a glove is finished

Sewing knowledge and quality points

First-line: It is one of the necessary materials in production. According to the more commonly used materials, it can be roughly divided into four categories:

1. 402 polyester thread (polyester cotton thread) open thread is generally used for denser and thinner materials, or for positioning.

Generally, the stitch length of the open thread is: 3cm9.5 stitches; the dark thread is: 3cm9 stitches; the positioning is: 3cm9 stitches + -1 stitches.

2. 202 polyester thread (polyester cotton thread) is more commonly used, generally used for car lining or positioning.

Generally, the stitch length of the open thread is: 3cm9 stitches; the dark thread is: 3cm8.5 stitches; the positioning is: 3cm8 stitches +-1 stitches.

3. 500D nylon (high-strength wire) is often used with PU. Generally, the stitch length of PU and canvas is: 3cm8 stitches; the fabric is 3cm8.5 stitches.

When we are preparing for production, we must first adjust the stitch length and stitches. General requirements: clear stitches, straight, moderate tightness, no throwing or skipped stitches. Concealed wires are allowed to have wiring, but they must be re-wired with 7-10 stitches, and stitch back and forth well. Needle pitch: open/dark threads are generally 7 to 9 stitches, and positioning is generally more than 8 stitches. Choose thread according to different product/data requirements. Do not use threads of different colors and specifications without authorization.

It is necessary to talk about our Lycra fabric, which is different from pure cotton.

a. Different ratios

Pure cotton fabric: the ratio is a fabric made of 100% cotton, Lycra cotton fabric: a ratio of 10% or a5% Lycra (a kind of elastic fiber, the scientific name is spandex) + 90% or 95% cotton;

b. Different flexibility

Pure cotton fabric: made of pure natural material, the resilience of pure cotton is not as good as Lycra cotton, but it is very soft; Lycra cotton fabric: with outstanding stretchability, for knitwear, its multi-directional extension is determined by the fabric itself Yes, Lycra brings only the elasticity of stretching and recovery. Clothing made of Lycra cotton has no sense of urgency and can stretch freely.

Pure cotton fabric: made of pure natural material, the resilience of pure cotton is not as good as Lycra cotton, but it is very soft; Lycra cotton fabric: with outstanding stretchability, for knitwear, its multi-directional extension is determined by the fabric itself Yes, Lycra brings only the elasticity of stretching and recovery. Clothing made of Lycra cotton has no sense of urgency and can stretch freely.

Pure cotton fabric: general moisture absorption; Lycra cotton fabric: with a special chemical structure, better moisture absorption.

Boodun process of making fitness gloves is probably like this